Development of mechanical carbon

What is Mechanical Carbon?

Carbon is a material composed of the element carbon (elemental symbol: C). This material is lightweight and strong, and is used in a variety of products. Fuji Carbon Manufacturing Co. is working on the development of mechanical carbon, which has high functionality among carbons and is used in industrial products.

Mechanical carbon has high self-lubricating properties so does not easily damage other materials, and is used for sliding and joining surfaces, bearings and gears. It also has excellent heat resistance, chemical stability, and high thermal conductivity, allowing it to be used in harsh environments (high temperatures, underwater, corrosive atmospheres, no lubrication). In addition, it has various material characteristics such as low specific gravity (light weight) and low noise, and it is expected to be used as a replacement material for metals such as copper, aluminum, and iron, as well as resins.

Comparison of characteristics

with typical materials

| Characteristic | Carbon (mechanical carbon) |

Copper | Aluminum | Resin |

|---|---|---|---|---|

| Coefficient of friction | 0.15-0.25 | 0.35-0.45 | 0.75-0.85 | 0.1-0.5 |

| Heat resistance | 400℃ | 300℃ | 300℃ | 150℃ |

| Specific gravity | 1.5-1.8 | 8.9 | 2.7 | 2 |

| Linear thermal expansion | 5×10-6 | 10×10-6 | 23×10-6 | 100×10-6 |

* This is a general value. However, it may vary depending on conditions.

It has excellent heat resistance, self-lubricating properties, chemical stability, and high thermal conductivity, allowing it to be used in harsh environments (high temperatures, underwater, corrosive atmospheres, no lubrication). In addition, it has the advantage of being low-noise and lightweight due to its low specific gravity.

Example of use

Bearings

Submersible pumps, domestic water heaters, etc.

Gears

Under development

Under development

List of developed materials

(typical characteristics)

For wet uses

| Grade | Bulk density g/㎤ |

Shore Hardness HSC |

Bending strength MPa |

Coefficient of friction | Linear thermal expansion coefficient 10-6/K |

Limit PV value MPa・m/s |

Heat resistance temperature ℃ |

|---|---|---|---|---|---|---|---|

| CX2011RG | 1.66 | 81 | 53 | 0.11 | To be measured | 10.4 | 250 |

| CX2011RH | 1.7 | 82 | 59 | 0.11 | To be measured | 14.2 | 300 |

| CX2121RH | 1.81 | 75 | 66 | 0.17 | To be measured | 10.4 | 300 |

For dry uses

| Grade | Bulk density g/㎤ |

Shore Hardness HSC |

Bending strength MPa |

Coefficient of friction | Linear thermal expansion coefficient 10-6/K |

Limit PV value MPa・m/s |

Heat resistance temperature ℃ |

|---|---|---|---|---|---|---|---|

| CX2111RE | 1.63 | 90 | 43 | 0.20 | To be measured | 19.6 | 250 |

| CX2111RG | 1.72 | 80 | 56 | 0.30 | To be measured | 9.8 | 300 |

| CX2111RH | 1.78 | 95 | 70 | 0.37 | To be measured | 3.7 | 300 |

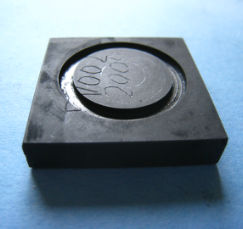

In-house evaluation equipment

Ring-on-disk test

(Reference JIS Standard)

Frictional wear test machine Test machine

・Measurement condition range (testing machine specifications)

・Load:10~100kg(0.5~9.8MPa)

・Number of rotations:30~2,000rpm(0.036~2.25m/s)

・PV value:0.02~22MPa・m/s

Ring

Test piece (disk)